4 Collection System and Facilities

- Success of the Return-It depot network.

- How the collection system works after consumers return their empty containers.

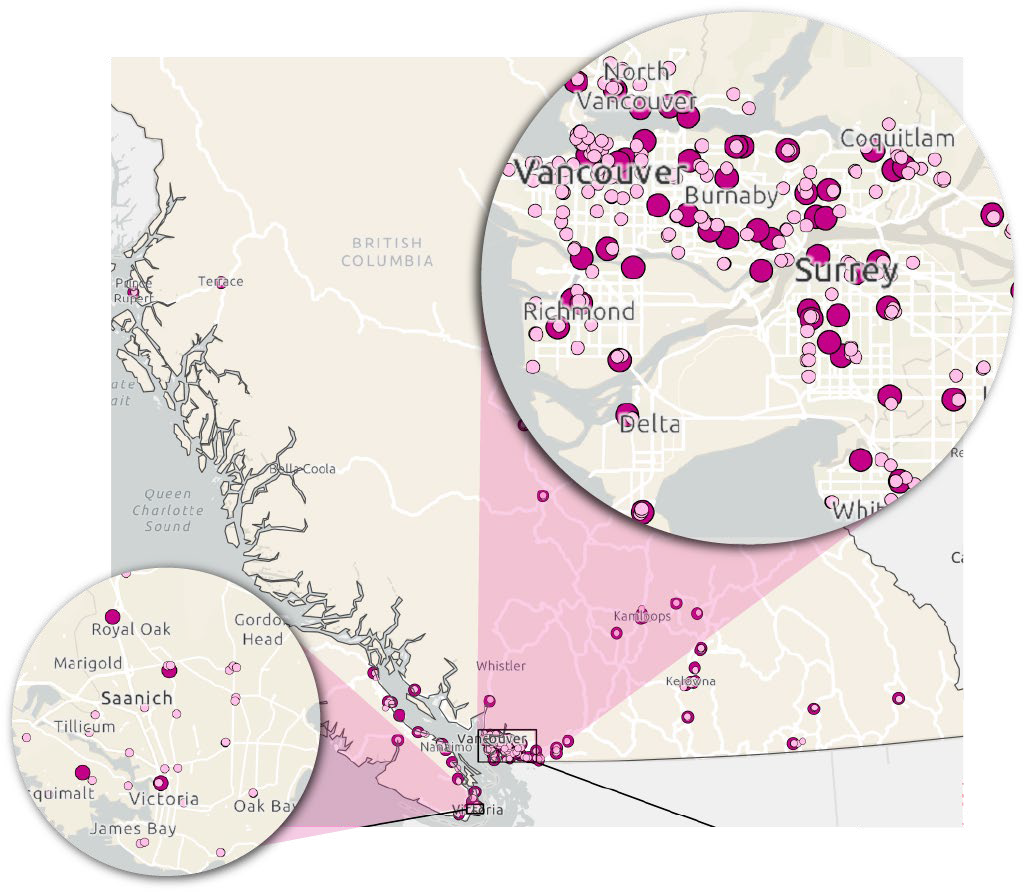

- Map of British Columbia pinpointing the depots and the processing sites.

4.1 Modernization and Innovation

Encorp’s evolving collection network consists of 163 independently owned Return-It depots, 2 urban Return-It Express Plus locations and 9 unstaffed Express & GO stations. Over the past several years, this network has become the backbone for many community-based recycling programs around the province. In 2021, Encorp focused on expanding our successful programs and on introducing additional innovations to ensure BC consumers have convenient access to a modern collection network. The Return-It Express program continued its rapid growth and popularity with consumers, providing them with a safe and easy recycling option.

The Return-It network consists of independently owned and operated Return-It depot collection facilities that have collection agreements with Encorp, as well as corporate Return-It Express Plus locations and Express & GO unstaffed stations. These locations have been a particular focus of innovation.

Encorp’s move to a unified deposit in 2020 simplified the system and allowed Encorp to introduce a new sorting procedure that provides reduced sorting for consumers at the depot and efficiency for our depot operations’ handling procedures. Termed “simplified sorts,” the new procedure changed the required number of sorts from 28 to eight by eliminating the need to sort by size and simply focuses on sorting by commodity type (i.e., aluminum, plastic, glass or polycoat). An independent study by an operational efficiency consulting firm concluded that the switch to simplified sorts resulted in savings of 23% in direct labour costs to handle the containers.

- Simplified Sorts and Depot Automation

-

This change to simplified sorts also paved the way for three of our busiest independent depots to deploy reverse vending machines and automated container-count technology to process containers received either over the counter or through Express. Consumers using these depots have adapted quickly to the changes and are pleased with not having to spend time at the depot sorting their containers. Depot operators benefit from the speed and efficiency of processing containers using automation technology, which allows them to utilize resources differently in a challenging labour market.

Return-It depots have become the de facto recycling hubs in communities across British Columbia. Other recyclables and end-of-life materials, such as electronics, PPP (plastic/paper/ packaging), batteries, small appliances, paint, light bulbs and motorized yard tools, can be recycled at depots that also participate in one of nine approved stewardship programs. Depots that participate in multiple programs ensure that the Return-It depots become a one-stop location for most consumer recyclables. The Return-It website indicates which other stewardship programs each depot participates in for consumer awareness.

- Collected Material Logistics

-

Moving the material collected by Encorp as optimally as possible is a central focus of our integrated logistics system. Encorp utilizes a network of partners comprising 38 transporters moving material into 15 processing sites throughout the province. Within urban centres, we use dedicated transporters that pick up from depots, retailers and other collection sites. In rural areas, Encorp utilizes transporters that provide back-hauling, resulting in environmental, logistical and financial savings.

This integrated system was put to the test during the numerous major weather events we had in 2021, in particular, the flooding that impacted major transportation arteries in the province. During this event, our crisis management team was mobilized, and we were able to work with our transport and processing partners to activate contingency and communication plans that minimized and shortened the disruptions to our collection network.

As announced last year, Encorp started utilizing Canada’s first-of-its-kind compressed natural gas (CNG) hybrid-electric compaction truck in the Lower Mainland to move plastic, gable top and Tetra Pak containers from depots to processing. This technology allows us to transport six times as much material in a single trailer as compared to a traditional trailer transporting uncompacted material. The success of this pilot led Encorp to expand the fleet, ordering two additional compaction units in 2021. Mobile compaction becomes particularly important with the pending addition of milk and plant-based beverage containers into the deposit system in 2022. Unfortunately, global supply chain issues delayed the receipt of those new units to 2022 from their original planned deployment in late 2021.

- Return-It Express

-

2021 proved to be another year of positive growth and consumer satisfaction for Encorp’s Return-It Express program. Our Express program registrations increased 42% over 2020, with over 55,800 new registrants bringing our total registrants to over 191,000. The program provides consumers with a convenient drop-and-go means of recycling their used beverage containers without the need to pre-sort them for refund at a depot. Return-It Express is offered at 78 Return-It depots as well as at our 2 corporate Express Plus locations and 9 Express & GO stations. Customers using Express simply place their containers in clear plastic bags, label the bags with their unique Express label and drop off the bags at their nearest Express location for counting. Deposits are placed into customer accounts for redemption by Interac e-Transfer or cheque.

- Express & GO

-

In line with our social purpose of “Fostering a World Where Nothing is Waste,” Encorp’s Express & GO stations transform end-of-life shipping containers and give them a new purpose to serve consumers beverage container recycling needs by offering Return-It Express at unmanned locations. Express & GO stations are often sited at transfer stations or co-located in the parking lots of our retail partners. Encorp’s Express & GO stations have become an increasingly popular option for consumers in underserved rural communities or high-density areas where siting a traditional depot is difficult because of rising real estate costs and/or zoning issues.

In our continued effort to expand consumer access to Express, Encorp opened four new Express & GO stations in 2021 to increase the total from five to nine locations. Encorp is working with other stakeholders on numerous additional Express & GO stations for deployment in 2022. The four new locations we opened in 2021 are the village of McBride, at the University of British Columbia, in the North Vancouver Superstore parking lot and at the Hartland landfill outside Victoria.

- Express Plus Expansion

-

Building on the success of our Yaletown Express Plus, Encorp opened a second Express Plus location in the densely populated Lower Lonsdale area of North Vancouver. Affectionately named LoLo Express Plus, this Express location provides a one-stop recycling centre for nearby residents through our partnerships. In addition to collecting used beverage containers through Express, this location collects textiles, batteries, small appliances, end-of-life electronics, light bulbs and light fixtures and delivers them to other stewards or partners for proper recycling.

We also piloted a new Express feature at LoLo Express Plus known as scan-in at drop-off. Customers dropping off their Express bags are asked to scan their labels thus confirming the date and time of the drop-off. As we expand this program to more depots, scan-in at drop-off will allow better tracking and insight for both customers and Encorp’s customer service team to ensure we can keep track of bags throughout the process from drop-off to counting and crediting deposits to Express accounts.

4.2 How the Collection System Works

Consumers take their empty containers to a variety of places to collect the deposit refund, and ensure they are recycled.

4.3 Collection, Transportation and Processing Map

Encorp contracts collection, transportation and processing through a regularly reviewed request for proposal (RFP) procedure. Routes are consistently monitored and adjusted for optimal efficiencies. Transporters pick up beverage containers from depots and deliver them to the nearest approved processor. They are then compacted and prepared for shipping to various recyclers. These steps ensure that, on a weighted basis, 81% of the kilometres a container travels will be in a compacted state, keeping greenhouse gas (GHG) emissions at a minimum.

Express Plus

Express Plus

Express & GO

Express & GO

Return-It Depot

Return-It Depot

Processing Plant

Processing Plant

Consolidation Site

Consolidation Site

Note: Map outlines collection, transportation and processing for all commodities except glass.

For detailed location search, please visit return-it.ca/locations.

4.4 GIS Mapping and Accessibility Analysis

Since commencing operations in 1994, we have established a comprehensive network of permanent collection locations where the public can conveniently return beverage containers covered within Encorp’s plan.

Encorp has engaged a third party, Licker Geospatial, to conduct a complete benchmark geographic information system (GIS) mapping analysis to ensure reasonable access as outlined in the Recycling Regulation. The criterion started with the premise of serving more than 97% of the province’s population.

Licker Geospatial has completed accessibility analyses for all Return-It facility locations using the 2021 population at the dissemination block level and three different accessibility standards:

- 1. 4-Kilometre Population Threshold

-

Defines urban accessibility as a facility within a 30-minute driving radius. For rural coverage (outside a census metropolitan area), assessed for communities where the census subdivision’s total population was equal to or exceeded 4,000, access is defined as passing standard if it is within a 45-minute driving radius.

- 2. 3-Kilometre Population Threshold

-

Identical to the 4-kilometre population threshold, with the exception of rural coverage (outside a census metropolitan area) being assessed for communities where the census subdivision’s total population was equal to or exceeded 3,000.

- 3. Revised Standard

-

Defines urban accessibility as a facility within a 15-kilometre radius. Rural accessibility is defined as within 60 kilometres when the community is within 200 kilometres of a census metropolitan area.

Using specialized Esri ArcGIS Pro processes, drive times and planar distances were calculated from each dissemination block’s centroid to the nearest facility in order to assess whether the resident population had sufficient access under the three standards. Access to 2020 and 2021 facilities was assessed on the respective years’ road network, though only 2021 population numbers were used, as census data is only available in five-year intervals and was thus the most accurate data available. Provincially, the following percentage of the population was found to have access to a Return-It facility under the previously described standards for both 2020 and 2021.

- 4-Kilometre Population Threshold 99.2% Access

- 3-Kilometre Population Threshold 99.2% Access

- Revised Standard 99.3% Access

Given the goal of 97% of the population (within the standard’s evaluation parameters of rural coverage) of having access to a Return-It facility, provincially, all three standards meet this target.

While the previously described analyses were completed for all Return-It facilities, including grocery and liquor store locations, access varies when only depots and Express & GO locations are considered. Under the same revised standard described previously, 98.89% of the population has passing access to the depots/Express & GO locations alone, a reduction of only .41% compared to when all facilities are included.