2 Program Outline

- Message from the Chair and CEO, successes and struggles in 2016.

- Our vision, mission statement and strategic business model.

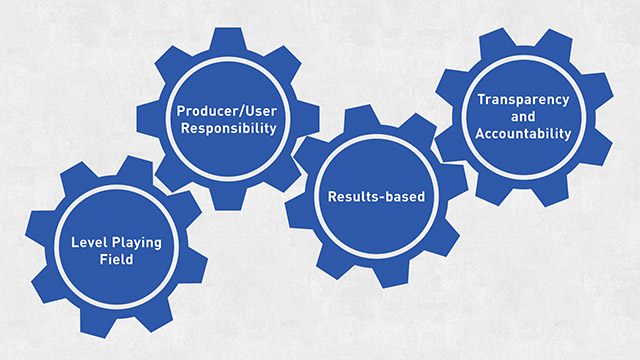

- The four key principles of industry product stewardship.

2.1 Message From the Chair

The past year extended our streak of accomplishments and improvements in the return system for used beverage containers and other recyclables in British Columbia.

Throughout the year, we either completed or significantly advanced key initiatives to improve the efficiency and performance of the Return-It depot network and to gain greater access and insight into hard-to-penetrate channels such as public spaces and the Industrial, Commercial & Institutional (IC&I) sector. Collectively, these initiatives constitute a series of base hits that drive overall system effectiveness and create a more convenient, satisfying experience for our customers. If there was one cloud in the sky, it was the year-end recovery rate which took a modest hit owing to some extraordinary circumstances, as Scott Fraser explains in his CEO’s report. We hope and expect that the return to a ‘normal’ environment will be reflected in the recovery rate for 2017.

Consumer research confirms that the Return-It network stands out at a time when British Columbians are faced with multiple stewardship programs and collection systems. Our investments in the brand and collection infrastructure, coupled with the ongoing support of our depot operator-partners, keeps the Return-It system highly-regarded and top-of-mind amongst B.C. consumers. It also enables Encorp to meet the provincial government’s expectations with respect to Extended Producer Responsibility (EPR) and, in doing so, to be one of the leading stewardship organizations in Canada.

Of course, none of this would be possible without the commitment of our partners – the processors who convert used beverage containers, waste electronics and other collected goods into new products and materials, the transporters who move the goods in bulk from point to point, the depot operators who collect them and interface with B.C. consumers, and the brand owners who undergird the entire system. Together we have fashioned a unique supply chain that responds to the needs and expectations of British Columbia consumers.

Within this system, the Board of Directors is responsible for ensuring that Encorp is both environmentally and economically sustainable. Accordingly, the board monitors the corporation’s business and financial performance throughout the year and ensures that reserves are maintained at levels sufficient to meet ongoing cash flow requirements without generating unnecessary accumulations. In 2016 the corporation’s planned operating deficit brought reserves into the targeted range.

A further responsibility for the board is to ensure Encorp’s sustainability over the long run, a theme that occupies much of our attention at annual strategic planning sessions. In this light, we are confident that we have the right business model to thrive as the world of product stewardship evolves. Over the years Encorp has built a robust depot-based beverage container return system that ensures that our stakeholders’ interests will be well looked after in the future.

Our management team continues to do an outstanding job of interpreting British Columbians’ recycling behaviour and identifying ways to make the Return-It experience more efficient, effective and memorable. Our sincere thanks go to all staff, as well as to our depot and supply chain partners for their roles in these important initiatives. And as always, we thank our members for their ongoing support of Encorp Pacific (Canada) and all its activities.

Dan Wong,

Board Chair

2.2 Message From the CEO

It was a two-steps-forward, one-step-back year in 2016. While we made great headway with some of our key initiatives, in the end we didn’t achieve the results we wanted on our primary goal, increasing the recovery rate.

Unusually snowy and icy conditions in the Lower Mainland and on Vancouver Island stopped consumers from visiting depots. Through November we were tracking to increase our recovery rate for the year. In December, though, returns dropped by 15 percent, or more than 10 million units, turning an increase into a decline.

Despite the setback, there were numerous areas of encouragement in the year.

For the first time since 2010 we collected and recycled over 1 billion containers. This eliminated the need for the extraction of virgin resources, reduced greenhouse gases by eliminating the production and transportation of new materials, and made B.C. a more attractive place to live through litter reduction.

At the same time, we increased efficiency and cost-effectiveness in the system. Over the past two years, through projects focused on materials handling and logistics, we have driven over $2 million in costs from the system. We have also upgraded key IT and logistics systems to reduce paperwork and provide timely information internally and to our partners.

All the while, we have remained focused on customer convenience and experience at Return-It depots, developing a new version of our point-of-return software, adding five new Return-It Express locations in the Lower Mainland and certifying six new depots in our Stars program, which rewards depots that invest in their customer environment.

As always, we thank our dedicated team at Encorp Pacific, the Return-It depots, and our transporters and processors for making it all happen, and to all the dedicated British Columbians who bring their containers back to us.

Scott Fraser, President and CEO

2.3 What Drives Us

- Vision

- To be the model Industry Product Stewardship organization in a province where every beverage container is recycled.

- Mission

- To deliver convenient, cost-effective and responsible collection and recycling systems for beverage containers and offer strategic service provision for compatible consumer packaging and end-of-life products.

- Role

- Our role as a stewardship agency is to facilitate brand owner/producer compliance with the Recycling Regulation by organizing recycling programs from collection and transportation through to final recycling into a variety of end-of-life packaging and products.

2.4 Encorp's Business Model

Since its inception, the Encorp business model has utilized outsourcing as the key component for delivering on its mandate.

Encorp has developed and maintained a set of core competencies within a small managerial and administrative team responsible for strategic planning, financial management, consumer awareness, infrastructure development, information technology and public transparency. All other operational activities are delivered through a network of independent contractors such as depot operators, transporters and processors. This contract management model allows Encorp to regularly test the market for cost competition without having to support any capital investments of its own.

The advantages of this model include:

Market-based costs – Regular reviews of costs ensure that any recent improvements in efficiency and technology can be exploited.

Scalability – Changes in demand can be accommodated rapidly.

Flexibility – Changes in market behaviour can be quickly adapted to.

Innovation – New ideas can be tested, assessed and, where feasible, incorporated into the overall business model.

In essence, the Encorp model is similar to that of many manufacturing industries which retain their key strategic strengths in-house but outsource most aspects of producing their products. The flexibility of this model makes it possible for Encorp to continue adapting to changing market trends.

2.5 Key Principles of the Industry Product Stewardship Model

The Industry Product Stewardship (IPS) model was first set out in a 1997 regulation called the Beverage Container Stewardship Program Regulation (BCSPR).

Our corporate structure, as a federally incorporated not-for-profit organization, was chosen specifically because it meets the requirements of this new style of regulation.

In September 2002, the provincial government further codified the principles to be followed in its Industry Product Stewardship Business Plan. In 2004, these principles were carried forward into the Recycling Regulation that replaced the 1997 beverage regulation and all others that existed at that time. The Recycling Regulation is a “framework” regulation enacted to apply to all extended producer responsibility (EPR) programs in British Columbia. Today, there are upwards of 25 approved EPR programs.

The key principles are:

Producer/User Responsibility – Responsibility for waste management is shifted from general taxpayers to producers and users. Responsibility is not shifted to other levels of government without consent.

Level Playing Field – All brand-owners for a particular product category are subject to the same stewardship responsibilities (including historical waste). All consumers have reasonable access to product collection facilities.

Results-based – Programs focus on results and provide brand owners flexibility with minimal government involvement. Programs are tailored for individual products and encourage continued innovation by producers to minimize environmental impacts during all stages of the product lifecycle, from product design to end-of-life management.

Transparency and Accountability – The program development process is open and provides all stakeholders the opportunity for input. Industry is accountable to both government and consumers for environmental outcomes and allocation of revenue from fees/levies.

Back to return-it.ca

Back to return-it.ca